SAFIERY UNIVERSITY

TEMPERATURES KILL

SHOCK ABSORBERS –

This technical article is designed to give value to the reader through more knowledge on the benefit of monitoring shcok absorber temperatures.

There is a great article by Matt Raudonics on a trek through the Canning Stock Route with a fleet of Mercedes G Wagons.

“Mercedes Benz had become the first vehicle manufacturer to take a convoy of standard vehicles up the 1600km of the Canning Stock Route, one of the harshest tracks in the country. There had been trials, tribulations and added expenses but all seven vehicles had made it on schedule.

The total damage toll ran to five tyres, four cracked wheel carriers, one rear view mirror knocked off and a few more damaged, two G 350s with non-operative airconditioning, two AdBlue tanks breaking their mounts, 10 shock absorbers and a cracked radiator hose from a reversing incident. “

The number that jumps off the page is “10 shock absorbers”.

When travelling over corrugations and difficult road/track terrain, significant energy is generatedin the shock absorbers and tyres. This increases the temperature of the tyres and shock absorbers.

The tyres and shock absorbers dissipate the heat. However, if more heat is being created than the tyres/ shock absorbers can dissipate, the oil in the shock absorber will over-heat causing the shock absorber to fail.

If the tyre sidewalls are generating too much heat, they can be vulnerable to failure too.

Over corrugations, the distance the shock absorber travels is very little. So the heat build up is concentrated. See the photo below of the “blue heat ring” on the shaft of the shock absorber caused by extreme temperature build up.

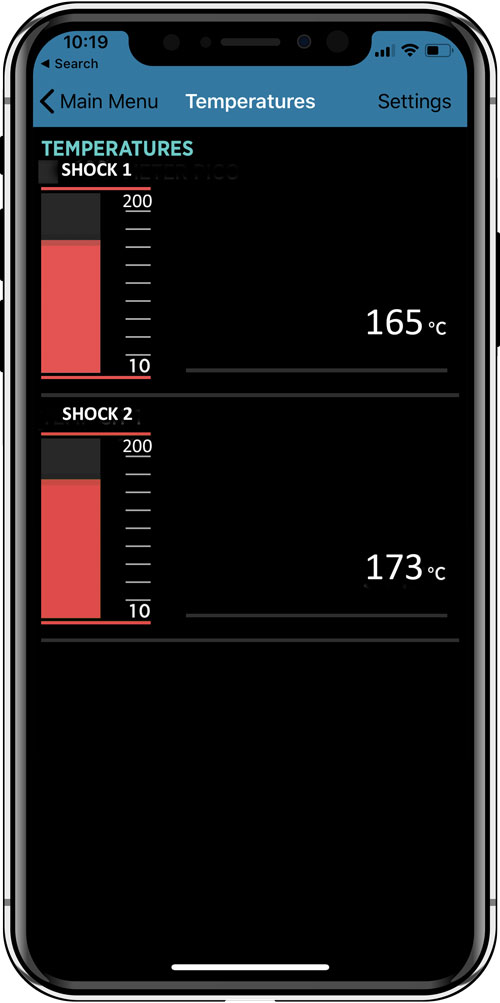

The design of the shock absorber is to efficiently dissipate this heat. If the heat build up is greater than the rate that the heat can dissipate, the shock absorber increases in temperature. If the temperature goes above 170C, even high temperature seals like “Viton®” will fail, the oil/nitrogen will dissipate, and the shock absorbers fail.

The simple way to prevent this is to monitor shock absorber temperature.

Monitoring Shock Absorbers:

-

Stainless Steel Temperature Sensor rated at 220 degrees+

-

Add Temperature Monitoring Module to SIMARINE Pico system

-

Load the SIMARINE App on your Smartphone

-

Set the alarm points!

Stainless Steel Temperature Sensor rated at 220 degrees+

- Have to be stainless steel,

- Connected with stainless steel braid. Avoid any rubber as this will just melt and potentially cause a fire.

- The sensor will be facing down with the entrance to the stainless steel head “open”. So, the Sensor needs to be long so that the seal can be waterproof.

- The sensor is clamped twice around the shock with pipe clamp ring.

Adding Temperature points to SIMARINE Pico System

- Use the T107 Module or the SCQ25t. Both of these take 4 temperature inputs.

- See modules below.

Set temperature Alarm points to SIMARINE Pico System

- Check seal type and temperature limit

- Use 20 degrees below this to a max of 140C to start with.

- Do a simple calibration test of ambient temperature on a typical day forst thing in the morning.

- SIMARINE has calibration and temperature adjustment.